Offering birds with the right home atmosphere is essential to unlocking the total genetic potential and efficiency of a flock. Poultry growers usually give attention to limiting home power and heating prices. Typically, this can be a false economic system because it results in a sub-optimal atmosphere which is detrimental to closing chicken efficiency and subsequently total revenue. Efficiency harm as a result of poor minimal air flow within the early phases of the flock are realized in the direction of the top of the cycle when it’s too late to right.

Brendan Graaf, Broiler Specialist, Cobb Europe

This text will cowl the important thing concerns and primary calculations for minimal air flow. The minimal air flow system is designed to make sure good air high quality and moisture management all through the lifetime of the flock, thus serving to to attain each optimum efficiency and chicken welfare.

Minimal air flow

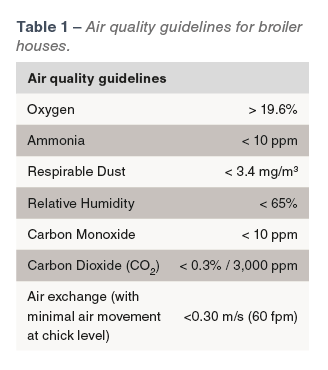

Minimal air flow is the minimal quantity of air flow (air change) required to keep up the total genetic potential of the birds by guaranteeing an enough provide of oxygen whereas eradicating moisture, waste merchandise, and combustion from the atmosphere. Desk 1 is a reference information for air high quality requirements that have to be maintained by the minimal air flow system.

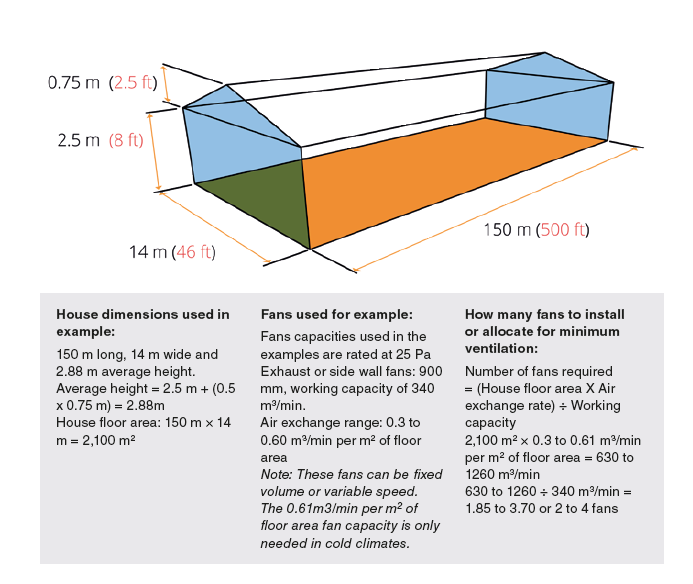

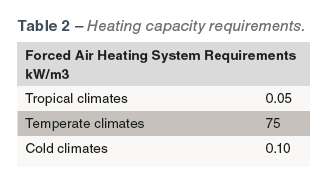

The system makes use of followers on a cycle timer and is impartial of temperature management. Poultry homes want enough heating capability (Desk 2) to keep up home set-points on the chilly days, whereas nonetheless permitting enough minimal air flow, because the minimal air flow system is the first supply of warmth loss from the home. The minimal air change is linked to the quantity of moisture added to the home by the birds, the consuming system, heating system and air flow system. Underneath most situations, sustaining good moisture management ought to provide enough air high quality for the birds and guarantee carbon dioxide ranges stay under 3000 ppm.

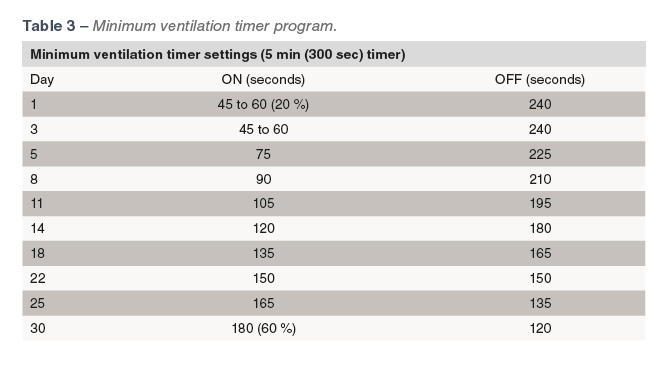

The popular cycle time for minimal air flow is a 5-minute (300 sec) on/off cycle with a minimal run time of roughly 20% of this time (5 minutes = cycle of 1 minute on, 4 minutes off). Any time the air high quality begins to deteriorate, small will increase (10 to fifteen seconds) to the ON time have to be made, however the whole cycle time ought to all the time stay the identical i.e. in the event you enhance the ON time by ten seconds you should take away ten seconds from the OFF time in order that the full cycle size stays at 300 seconds. The minimal time the followers are turned on must be roughly 60 seconds to make sure enough mixing of the chilly incoming air with the nice and cozy inside air and enough extraction of moisture by way of the exhaust fan. Nevertheless, if your own home solely has massive (1.2 to 1.5 m/ 50 to 60”) tunnel kind air flow followers versus the smaller (600 to 900 mm /24 to 36”) minimal air flow followers then the cycle on time might be lowered to attain comparable air change charges.

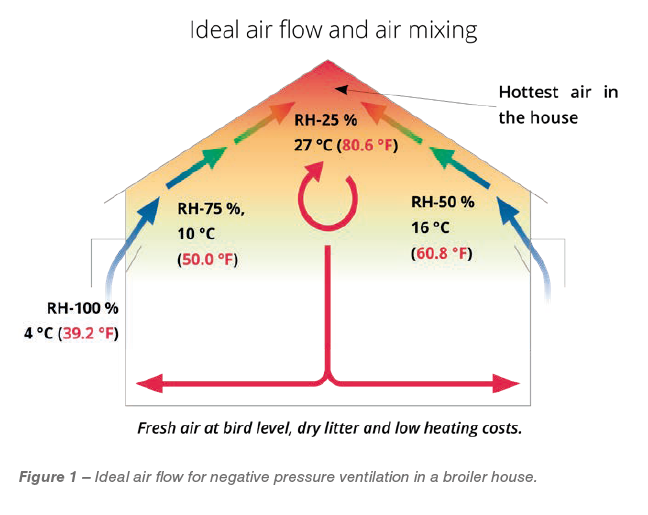

The incoming chilly air have to be conditioned appropriately by simply attaching to the ceiling, transferring in the direction of the height of the home the place it’s heated, broaden and its relative humidity lowered. The air jet should then begin detaching from the ceiling close to the centre of the home producing a return motion at ground degree in the other way. This return motion in the direction of the aspect partitions will guarantee distribution of the hotter dry air thus bringing recent air to the birds whereas additionally eradicating moisture and waste gases from the litter, the birds, and the heating system (Determine 1).

The stale moist air is then extracted from the home by way of the followers. The system runs when the home is at or under set level temperature and can function on a timer program – see the instance of a easy timer fan program under (Desk 3).

The timer fan capability needs to be a minimal of 0.3 m3/min per m² (1.0 cfm per ft²) in sizzling climates the place outdoors temperatures not often drop under 20 to 25 ⁰C (68 to 77 ⁰F). In chilly climates a timer fan capability of 0.61 to 0.77 m3/min per m2 (2 to 2.5 cfm/ft2) of ground space, shall be wanted. The problem will all the time be matching the requirement with followers out there available in the market. Don’t use massive tunnel followers for the minimal air flow system, smaller capability followers will all the time afford extra steady environmental management and suppleness.

Some air flow methods don’t use cycle timer packages for minimal air flow, however as an alternative run a steady air flow system utilizing variable velocity followers. These methods are designed to supply a extra uniform home atmosphere, however it’s strongly dependant on the followers stress stability at low rpm. In sensible phrases can the incoming “air jet” connect to the ceiling to supply efficient conditioning of the chilly incoming air? These methods would require good high quality environmental controllers, perimeter inlets and followers. They don’t seem to be appropriate for older (leakier) homes and can usually require the next degree of technical data.

Instance calculation

The sizing and run instances needs to be adjusted to swimsuit a person home however the primary rules stay the identical. The minimal air flow cycle run instances are solely pointers and every day changes needs to be made primarily based on air high quality and sustaining humidity under 65 % the place doable. If the variety of followers works out to be lower than 1, then cycle on time might be adjusted to lower than 60 seconds to keep up right air change charges and never over ventilate the home. Some newer controllers use m3/chicken/hr as an enter setting for his or her minimal air flow charges. To be able to convert to those models, first calculate the full air flow capability at every age primarily based on the variety of followers used and the cycle timer program after which divide by the variety of birds in the home.

E.g. Capability of two followers = 40,800 m3/hr

Cycle time at day 0 = 60s ON; 240s OFF = 20% run time

Complete capability on cycle time = 20% of 40,800 m3/hr

= 8160 m3/hr

Home has 40, 000 birds, so = 8160 m3/hr ÷ 40 000 birds

= 0.20 m3/chicken/hr

Static stress check

The variety of followers to run for minimal air flow has been calculated and a timer program for his or her run time has been designed. Subsequent, you will need to obtain right air con. First, we have to guarantee the home is as air tight as doable with a view to successfully generate a damaging stress and guarantee air enters by way of the inlets and never by way of leaks or gaps round the home. Conducting a static stress check will let you understand how tight or leaky your own home is. As soon as a tightly sealed home has been established you will need to guarantee right inlet administration.

Inlets

Vital factors about inlets:

- Minimal air flow inlets needs to be sealed particularly on the hinge, sides and alongside the main edges, to forestall the chilly air being directed all the way down to the ground.

- When open, the air ought to solely enter excessive of the inlet and never from the edges or by way of the underside of the inlet

- All minimal air flow inlets ought to direct air in the direction of the height of the home. The stress drop throughout the inlets needs to be adjusted to make sure that the incoming air reaches the height the place the warmth has amassed.

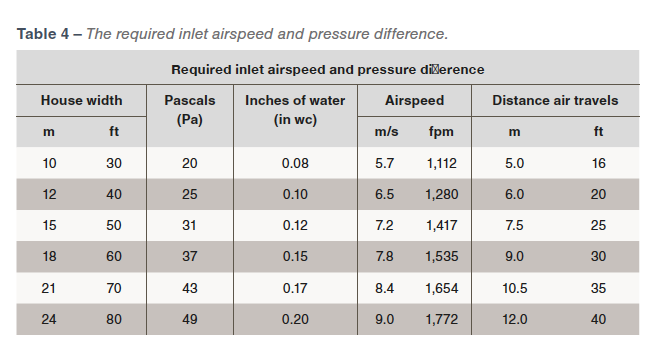

- The stress drop chosen will rely on the width of the home or how far the air should journey as soon as it enters the home.

- Right air stress is achieved by matching the inlet space and the fan capability.

- Air inlets needs to be stress managed to keep up fixed air velocity all through the air flow phases.

- Desk 4 can be utilized as a reference for the right static stress/inlet air velocity required to make sure incoming air stays as near the ceiling till it reaches nearly half manner throughout the home.

- The stress drop chosen will rely on the home width, how far the incoming air jet should journey as soon as it enters the home, and the skin temperature.

- When outdoors temperatures are under 5 °C the inlet stress drop, and opening measurement will have to be elevated. The power of the incoming air jet to connect to the ceiling is dependent upon the temperature differentials between inside and outside the home.

- At all times use a smoke check to make sure that the incoming air reaches the centre of the home. Smoke exams ought to solely be executed when the skin temperatures are considerably colder than inside, and when there isn’t a wind.

- Inlets have to open sufficient to attain the required static stress and airflow. Relying on inlet design, a minimal opening of two.5 to five cm is required to make sure chilly air reaches the centre of the home.

- Inlets needs to be put in as near the ceiling as doable – about 30 cm under the eaves offered there isn’t a interruption of airflow.

- In open truss homes, the angle of the inlet opening have to be such that the air shouldn’t be directed onto a purlin which is able to redirect the air all the way down to the ground.

- Any obstructions (electrical conduit/concrete or wood beams) needs to be eliminated as a result of they interrupt the air circulation, forcing air to the ground.

- Within the case of current obstructions, a directional flap can be utilized on high of the inlet and/or a stable “air ramp” to assist the air in passing the obstruction.

- When utilizing a damaging stress air flow system, it isn’t the location of the followers which dictate uniformity of air distribution however relatively the location of the inlets.

- To attain uniform air distribution, inlets needs to be evenly unfold all through the home and open the identical quantity.

- Homes over 100 m (330 ft) ought to have the inlet drive models put in within the centre of the aspect wall to scale back any inlet opening variation. Stable 5 to eight mm (0.2 to 0.3 in) metal rods get rid of any stretch and twisting.

- It is not uncommon for cables to stretch and twist and may trigger variability in perimeter inlet openings. Inlets nearer to the drive unit are open greater than these on the finish of the home. This may be minimized by guaranteeing a sufficiently sized counterweight or spring.

- Information pulley place and measurement is essential for environment friendly closing and sealing of inlets.

- All inlets require wind proofing covers on the skin of the home. The inlet cowl needs to be at the very least 30% greater than the cross-sectional space of the inlet to reduce air restriction. These inlet covers additionally assist to scale back pure gentle getting into the home.

On the subject of minimal air flow, there may be not often a one measurement matches all answer. Nevertheless, by making use of the data from this text along with good stockmanship, equivalent to making every day changes to minimal air flow primarily based on air high quality, humidity, and chicken behaviour, will drastically help with offering an optimum atmosphere to reaching glorious chicken efficiency.